Forged vs. Wrought Steel: Key Differences, Applications, and Advantages?

When it comes to metal manufacturing, two terms often appear side by side: forged and wrought. Though they may seem similar at first glance, they represent two distinct categories of metal processing with unique characteristics, performance advantages, and applications. Understanding the difference between forged and wrought metals is essential for engineers, manufacturers, and buyers when choosing the right material for their specific use.

In this article, we’ll explore the differences between forged and wrought metals in terms of definitions, manufacturing processes, mechanical properties, standards, product examples, and more.

1. What Does Forged Mean in Metal Processing?

Forging is a deformation process that involves applying compressive forces to metal, typically at high temperatures, to shape it into the desired form. Forging can be done by hammering, pressing, or rolling the metal using dies.

Key Features of Forged Metal:

- Refined grain structure

- High strength and toughness

- Better fatigue resistance

- Fewer internal voids or inclusions

Common Forged Products:

- Flanges

- Shafts

- Rings

- Gears

- Pressure vessel components

Types of Forging:

- Open-die forging: Ideal for large components.

- Closed-die (impression die) forging: Used for more precise shapes.

- Seamless rolled ring forging: Often used in aerospace and power generation.

2. What Is Wrought Metal?

The term “wrought” refers to metal that has been mechanically worked into its final form, typically by rolling, drawing, extruding, or forging. The key idea is that wrought metals are not cast, meaning they were not poured from molten metal into molds.

Characteristics of Wrought Metal:

- Ductile and malleable

- Uniform grain structure

- Easier to machine and weld

- Good surface finish

Common Wrought Products:

- Pipe and tubing

- Elbows and tees

- Plate and sheet metal

- Wire and rods

- Structural shapes (I-beams, angles)

3. Key Differences Between Forged and Wrought Metals

| Feature | Forged Metal | Wrought Metal |

|---|---|---|

| Definition | Compressed under high pressure | Mechanically worked but not cast |

| Grain Structure | Aligned and refined | Uniform but less dense |

| Strength | Higher strength and toughness | Moderate strength |

| Applications | High-pressure, high-stress parts | General structural applications |

| Process | Forging press, hammer, die | Rolling, drawing, extruding |

| Cost | Higher due to tooling and energy | More economical in large quantities |

| Surface Finish | Rougher surface (can be machined) | Generally smoother surface |

4. Standards and Certifications

Forged Products:

- ASTM A182 (Forged or Rolled Alloy and Stainless Steel Pipe Flanges)

- ASTM B564 (Nickel Alloy Forgings)

- ASME B16.5 / B16.47 (Forged Flanges)

Wrought Products:

- ASTM A403 (Wrought Austenitic Stainless Steel Pipe Fittings)

- ASTM A240 (Wrought Stainless Steel Plate, Sheet, and Strip)

- ASTM A554 (Welded Stainless Steel Mechanical Tubing)

5. Which One Should You Choose: Forged or Wrought?

The choice between forged and wrought metal depends heavily on the application requirements:

Choose forged metal when:

- The part is subject to high stress or pressure (e.g., high-pressure flanges, critical shafts)

- Superior strength and fatigue resistance are required

- Dimensional integrity is critical under load

Choose wrought metal when:

- The component does not experience extreme loading

- Machinability and weldability are important

- High-volume production is needed at lower cost

6. Industry Applications

| Industry | Forged Products | Wrought Products |

| Oil & Gas | High-pressure valves, flanges | Pipe fittings, elbows |

| Aerospace | Jet engine parts, turbine disks | Structural panels, brackets |

| Automotive | Crankshafts, connecting rods | Body panels, exhaust tubing |

| Power Generation | Turbine rotors, rings | Condenser tubes, sheet metal |

| Construction | Load-bearing joints | Beams, structural profiles |

7. Metallurgical Insights: Why Forging Makes Stronger Metal

Forging realigns the grain flow to follow the shape of the part, eliminating discontinuities and grain boundaries that act as weak points. This grain refinement makes forged components significantly stronger and more reliable in fatigue-sensitive environments.

Wrought materials also benefit from mechanical working, but the internal structure is less optimized than in forged parts.

8. FAQs About Forged and Wrought Metal

Can a metal be both forged and wrought?

Yes. “Wrought” describes the general state of being plastically worked, and forging is one type of wrought process.

Is cast metal the same as wrought?

No. Cast metal is made by pouring molten metal into a mold, and tends to have larger grain structures and more porosity.

Which is better for corrosion resistance?

Corrosion resistance depends on the material composition. However, forged materials can offer better resistance in some environments due to reduced porosity.

Is wrought steel stronger than forged steel?

Generally no. Forged steel is stronger because of better grain alignment and fewer internal defects.

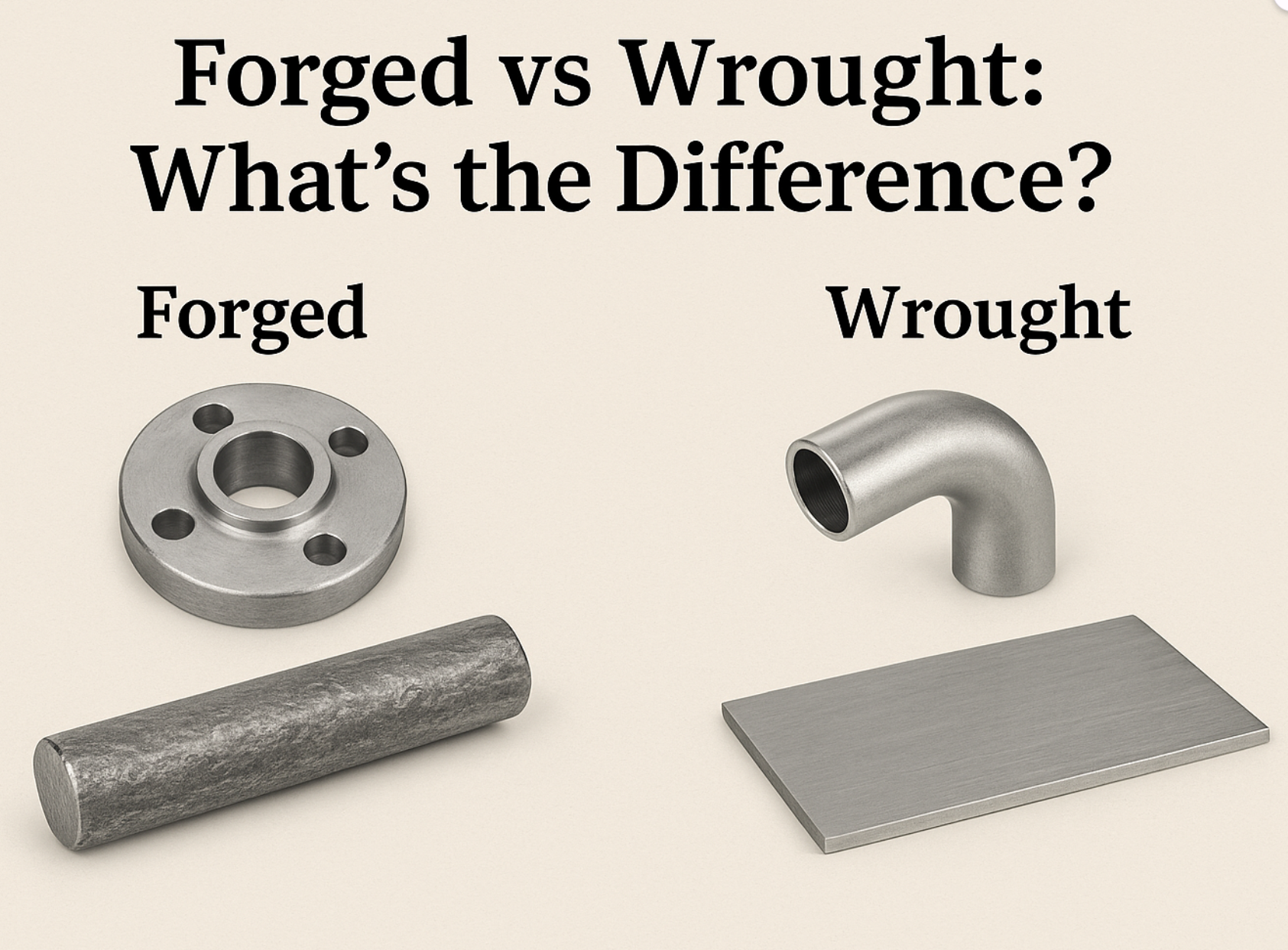

9. Visual Comparison: Forged vs Wrought Metal Products

(Include comparison image showing forged flange and rod vs wrought elbow and sheet)

10. Conclusion: Know Your Metal, Choose with Confidence

Understanding the differences between forged and wrought metals is crucial in engineering and industrial applications. Forged components offer superior strength, fatigue resistance, and grain structure, making them ideal for high-stress parts. Wrought components, on the other hand, provide cost-efficiency, uniformity, and excellent formability for general uses.

When selecting metal products for your project, always consider:

- Application environment

- Required mechanical properties

- Industry standards

- Manufacturing budget

Whether you’re sourcing stainless steel flanges or elbow fittings, knowing the manufacturing background—forged or wrought—helps ensure you choose the right metal, with the right performance, at the right cost.